|

BARRIER LAMINATIONS GIVE BROAD RANGE OF PROTECTION

Webster defines a barrier as a

"material object or set of objects that separates, demarcates,

or serves as a barricade." But today, barrier materials, when

used in packaging, offer so much more that the topic is worth a

little elaboration.

Barrier material consists of

base material such as polypropylene, polyester, aclar, foil,

paper, tyvek and nylon, that is laminated for additional

strength and protection to polyethylene, ethylene acrylic acid,

and Surlyn (lonomer). The laminating process extends the

versatility of the barrier by providing additional protection

against water, grease, acid, chemicals, corrosion and

atmospheric changes. The material can be formed into bags, or

can be used as sheets, blankets, or shrouds.

The three functional elements

of today's flexible packaging are barrier, machineability, and

sealability. Barrier packaging seldom has one single substrate

satisfy all of these functional requirements. Consequently, you

must combine various materials to meet specific needs.

The work horse of the

laminations business is paper/polyethylene/ aluminum

foil/polyethylene. Examination of this structure in light of

the three functional elements shows:

Barrier - Aluminum foil is the

most cost-effective gas and water vapor barrier material. It has

no inherent strength .

Machineability - Paper is the

most cost-effective material which has the physical strength and

stiffness for machineability.

Sealability - Polyethylene is

the most cost-effective heat sealing material.

Typical base substrates used in

barrier laminations in ascending order of cost are: Paper,

Polypropylene, Polyester, Nylon, and Tyvek. Typical sealants

used in flexible packaging in ascending order of cost are:

Polyethylene, Linear Low Density PE, Ethylene Acrylic Acid, and

Surlyn (lonomer).

Made with any number of

flexible barrier materials, custom pouches or bags are used

extensively commercially in the pharmaceutical, electronic,

chemical, dried food, photographic, bulk vitamin and packaged

powder industries. Heat sealing the bag provides the ability to

store an item for an indefinite period of time, fully protected

according to product specifications.

Some pouches offer

moisture-vapor protection and, when combined with a material

impervious to light, are widely used in the packaging of light

sensitive chemicals and photography supplies. Other pouches

provide a flexible, heat-sealed barrier material, for

applications that require protection against the build-up or

retention of Electro-Static charges. These pouches are

especially suitable for packaging electronic parts and equipment

for storage and shipment.

BARRIER BAGS, SLEEVES AND TUBING--INTERIOR PACKAGING

MIL B-117 covers heat sealable,

interior packaging bags, sleeves and tubing required by the

Military Services for the protection of supplies during

transportation and storage under all climatic conditions.

Intended Use. The bags, sleeves

and tubing covered by this specification are intended for use as

containers to provide various degrees of protection to the

contents. Transparent bags are intended for use where

transparency is desired to facilitate visual inspection of the

enclosed product.

Bags shall be formed using two

sheets or by folding one sheet of material. Heat sealable

surfaces of the specified material shall be placed face to face.

Heat sealing along both sides and the bottom edge. Transparent

bags fabricated by the side weld process shall be folded and

have two side seams. The side seams shall be parallel to each

other and the outer edge of the bag. The bottom seam shall be at

right angle to the side seam. When specified, bags 12 inches or

less in length, with a mouth opening of 10 inches or less, shall

be provided with a lip by extending one edge of the mouth 1/8

inch ( + 1/16 inch) beyond and parallel to the outer edge. The

length of the lip shall not be included in the dimensions of the

bag. Bags fabricated from sleeves or tubing shall consist of a

bottom seam and do not require a lip.

FLOWABLE CUSHIONING

A variety of competitive loose

fill and free-flowing materials are available. The vast majority

are made of expanded polystyrene and their cost per cubic foot

is lower than most other packaging materials.

Flowable cushioning floats your

product to prevent damage during transit. Millions of tiny air

bubbles in the foam act as shock absorbers to cushion bumps and

jars. Most flowable cushioning interlock to hold your product

securely in position. There is no shifting or settling to expose

an item to damage.

Flowable cushioning eliminates

the need for a variety of expensive packaging materials such as

die-cut inserts, corner blocks and molded foam parts. Many

products, regardless of size, shape or weight, can be easily and

economically packed in standard carton sizes with loose fill

flowable cushioning.

Shrink Wrapping

By Richard Buchau National

Sales Manager Shanklin Corporation

Shrink wrapping is placing a

tightened wrap around a product and/or group of products.

Shrink packaging usually

involves two steps: (1) wrapping the product in a full or bag

wrap; (2) applying heat to shrink the film tight and neatly

around the product.

Shrink-film usage involves two

distinct groups: (1) polyolefin films and (2) polyvinyl

chlorides (PVC). These are used for a normal retail application,

where appearance is a major criterion. A shrink polyethylene is

also available. There is a wide variety of shrink films

available with a range of properties and characteristics to

allow the many options needed for performance and desirable

economy. In normal applications, a three-dimensional item is

placed into a flat two-dimensional pouch. This will produce

excessive film in the corners that should be shrunk up tightly

against the corners of the item being wrapped.

Semi-automatic, automatic, and

form-fill-seal type wrapper are offered in single or two web

film models. Major consideration in selecting a wrapper would be

product size, pattern flow, cycles per minute, whether

centerfold, flat, sleeve or a bag-type film, custom design and

cost.

As for tunnels, factors to

consider are size of tunnel, speed in feet per minute, heating

method, air velocity, conveyor speed and cost.

Once the product has been

properly wrapped, the next step is to shrink the film tightly

around the item being wrapped. To do this, not only heat but air

velocity or turbulence within the tunnel is needed from all

directions. This will properly excite the air which will act as

a temporary superstructure to raise and support the film away

from the item so it can be heated to the proper temperature to

release the shrink energy. If not, the item will act as a

heatshrink and improper or partial shrinkage will result. An air

hole in the sealed bag will allow gradual reduction of air

pressure within the package and the film will draw tightly

against the item.

Stretch Wrapping

By Patrick R. Lancaster IL.

President Lantech, Incorporated

Stretch wrapping is the method

of unitizing and protecting pallet loads or groupings of

individual containers of product by applying layers of plastic

film. The film is mechanically stretched to increase its yield

and create a rubber band effect to keep the load unitized.

There are basically two

approaches in stretch wrapping: pass-through and rotary.

In pass-through systems, a roll

of film is located on each side of the conveyor system. The

ends of the rolls are joined by a heat seal, forming a film web

across the conveyor and through which the pallet load passes. As

the load moves through the wrap area, the film is pulled around

the front and sides of the load. The back of the load is

covered as the sealing heads move together and seal the film

ends. Pass-through systems are typically automated and use webs

of film which are approximately the same height as the loads

being wrapped. This method applies a single layer of film,

typically ranging from 3/4 to 3 millimeters thick.

With rotary systems, the wrap

cycle is accomplished by rotating the load on a mechanically

driven platform and applying multiple layers of film, ranging

from 1/2 to 1-1/2 millimeters thick. Yield is between 20 and

300 per cent. Rotary systems can be either spiral or full web in

terms of the manner in which they apply film.

The spiral approach uses a 20-

or 30-inch film web which moves up and down the load during the

rotation cycle. This method provides the flexibility to

accommodate loads of varying height. It allows the operator to

program the placement of the film on the load by regulating the

speed of the up and down travel and selecting the wrap counts

which apply additional layers of film to the top and bottom of

the load. The full-web approach similar in some respects to the

pass-through method, uses a web of film ranging from 40 to 85

inches in width. The web width is selected to match the height

of the loads being wrapped. As the load rotates, a full web of

film is applied, covering the entire surface of the load with

each revolution.

Basically, there are two

methods of elongating or stretching film--conventional or

pre-stretch.

The conventional design uses a

friction or magnetic brake on the film roll shaft or mounted

against the film roll. The function of the brake is to restrict,

to a degree, the unwind of the film. As the load rotates, it

generates a pulling force on the film, and the difference

between there restricting force of the brake and the pulling

force of the load creates the film stretch.

In the pre-stretch method, the

film is stretched primarily before it is applied to the load.

The film passes between or around two rollers, the second

turning faster than the first. Generally, the rollers are

mechanically connected or electronically controlled to regulate

the speed differential. Pre-stretch isolates the load from a

significant portion of the forces it takes to stretch film and

consequently allows higher film stretch.

Stretch can be changed by

altering the mechanical ratio of the two rollers and thereby

increasing or decreasing the speed differential between them.

The addition of a motor provides assistance to the roller

rotation and produces a greater range of flexibility to adjust

or regulate the amount of stretch force that is applied to the

load by the film.

Stretch ability is the measure

of how far a given film can be stretched over a given load

profile. To the load, stretchability is important because the

amount the film is stretched determines the force exerted by the

film on the load.

Often overlooked, restretch

force is the measure of the force available to restrict further

movement of the load once it is encapsulated in film.

The higher the restretch force,

the more effective the load unitization.

Film strength or breaking

strength is another important film load-holding property. Quite

simply, film strength is the measure of the ultimate force which

can be brought into holding the load before film failure.

Strength is especially important in sustaining or arresting the

forces of impact. The strength value of film is generally

expressed in terms of pounds per square inch of cross-sectional

area, or simply psi. And, depending upon the film type,

strengths may range from 2,500 to 7,000 psi.

Stretch-wrap equipment

Today's stretch-wrap equipment

offers a broad range of machine configurations, production

capabilities, features and operator requirements.

The simplest method involves a

hand-held roll of film, 10 to 20 inches in width, with a

mechanical stretch mechanism for spiral wrap or top banding

applications. The operator walks around the load and applies the

film. There are also wheel-mounted assemblies which can be

pushed around the load generally for full web applications, and

turntables or platform devices which are foot-pedal controlled

to rotate the load as the operator applies film from a hand-held

dispenser.

Platform-turntable units vary

greatly in price, performance and operating features. The load

is placed on a turntable by a fork lift or pallet jack. The

operator attaches the film to the load and then activates the

wrap cycle. The turntable rotates, and the film, either spiral

or full web depending on the model, is applied to the load.

Several variations of the

platform approach allow the pallet to remain stationary while

the film-dispensing mechanism moves around the load.

"Straddle-type" models are designed with an overhead-mounted

film arm which rotates around the load, and robot models that

travel around the perimeter of the load.

Gravity roller and powered

conveyorized semi-automatic models are intermediate in operation

and price between platform and fully automatic systems. Loads

are fed by conveyor into the wrapping zone, wrapped and

discharged to an exit staging conveyor. These systems are

typically loaded and unloaded by forktruck. They require an

operator to sequence the pallets, attach the film to the load

and activate or control the wrap cycle. Their greatest advantage

is the increased production capability they offer over platform

units.

Fully automated conveyorized

systems are available in pass-through and spiral or full-web

rotary models. Product loads are fed into the infeed conveyor

system by palletizer, load former, robot or fork truck. The

loads are staged on the infeed conveyor system and automatically

sequenced into the wrapping station. The load is wrapped and

then discharged onto the exit conveyor system. The entire

program is automatic, and no operator is required.

Of growing interest is stretch

bundling, the unitizing with stretch film of a group of

individual products, in less than pallet-load quantities.

Generally, two or more bags, cartons, rolls or sheets are

stretch wrapped together to create a bundle. As with pallet

overwrap applications, the film holds the bundle together and,

at the same time, provides product protection from contamination

or damage. This form of stretch bundling has become a popular

replacement for more expensive corrugated and heavy or specially

treated kraft containers.

Shrink Films

By Fred Calmes Films Market

Development Manager Cryovac Division, W.R. Grace & Company

Most shrink films are

manufactured from polyolefin resins (primarily polyethylenes,

ethylene-propylene copolymers, polypropylenes and

ethylvinylacetates) or polyvinyl chlorides. The types of films

produced from these resins range from industrial commercial

grades, such as shrink polyethylene, to specialized commercial

products such as polyvinyl chlorides, blended monolayer

polyolefins and co-extruded polyolefins.

Generally speaking, the shrink

polyethylenes are used in bundling, individual case wrapping,

carton palletizing and other non-retail applications. Polyvinyl

chlorides and polyolefins tend to be used in retail display

items which need the special marketing and merchandising

attributes these films exhibit.

Shrink films were first

introduced in the early 1960's and were generally used to

contain products and prevent pilferage or as dust covers to keep

products clean. One of the early marketing break throughs

brought record albums from behind the counter into a

self-service, mass-market concept. The clarity and gloss of the

new films also enhanced the graphics of the record jacket.

Previously, LPs had been wrapped in a hazy, non-shrink

polyethylene.

With the advent of larger

stores and the increased emphasis on self-service, shrink films

began to play a major role in merchandising thousands of

products. The optics and cleanliness of shrink film lent a

quality image as its use expanded into hardware; household

items; all types of paper goods including stationery, gift wrap

and greeting cards; prepared foods such as fresh or frozen

pizza, taco shells and dairy products; automotive accessories;

and toys, games and hobby kits.

Shrink films are available in

center-fold or single-wound form in thicknesses ranging from 50

to 150 gauge for polyolefins and up to 200 gauge for

polyvinylchloride (PVC). Center-folded films are used on L

sealer equipment. The package is placed on the loading tray and

transferred into the seal area where a hot-wire seal is made on

the open front and side of the film. A small vent hole is formed

on the film to allow air to escape during the shrink process.

The product is then conveyed into a hot-air tunnel where the

film initially balloons and then shrinks tightly to the package.

Depending on product size, speeds of up to 15 packages per

minute can be obtained on manual L sealers and up to 30 per

minute on automatic L sealers.

Higher speeds can be attained

using horizontal or vertical automatic form-fill-seal equipment

with single-wound film. In this process, a specially designed

forming shoe is used to wrap the film around the product. It's

secured with a static or thermal lap seal on the bottom or side

of the package and by a hot-wire or hot-knife trim seal on the

front and back. Complete and carefully designed packaging

systems consisting of automatic infeeds, indexers, collators,

high-speed shrink tunnels and collecting areas can reach speeds

of up to 250 packages per minute.

Industrial grade polyethylene

film may have a variety of end uses, especially when packaging

speeds or film characteristics aren't critical. It's often used

for bundling large cartons or over wrapping trays containing

canned goods or beverages. Available in very thick gauges, it

can also be used to protect heavy items during shipment. Since

it is hazier than most other shrink films, it is not usually

recommended for packaging retail items.

PVC resins, due to their

high-density, amorphous molecular structure, enable

manufacturers to create films with very specialized properties.

For example, they're a good choice where low shrink tension is

necessary. The new soft-shrink polyolefins are also a viable

option for such items as flat sheets of gift wrap, stationery,

single-set sheets, pillow cases and other textile products.

Another feature of PVC is the

ability, during the manufacturing process, to vary the shrink

tension in longitudinal and transverse directions. Having a high

percentage of shrink in one direction enables it to run on

sleeve-wrap equipment, resulting in the common "bull's eye"

package with circular openings at both ends. When produced with

mono-axial shrink, it makes excellent neck bands for

tamper-evident packaging.

Finally, PVC has very good

clarity, a wide seal-temperature range and low-temperature

shrink. The latter two characteristics enable this family of

films to perform well on less expensive sealers and tunnels

and/or poorly maintained equipment.

Some of the limitations

encountered with PVC include loose packages due to low shrink

tension, weak and charred seals marked with pinholes and film

relaxation. In addition, the film must be stored at least at

room temperature or below to prevent shrink-back. It can also

become quite brittle at temperatures below freezing, causing

problems when wrapping products that are frozen and/or shipped

during the winter. Unless seal temperatures are closely

controlled and the packaging area vented, equipment corrosion is

common. Over a prolonged period of time, these films will also

tend to become brittle and discolored.

Polyolefins, because of their

crystalline molecular structure, offer a wide variety of

characteristics. They usually appear in formulations of

high-density or low-density polyethylenes, linear-low or linear

medium-density polyethylenes, ethylene/propylene copolymers,

ethyl vinyl acetate, or multilayered combinations. They are

dimensionally stable and biaxially oriented to provide a

balanced shrink. They are tough and clear. And due to their

higher shrink tension, they shrink very tightly to the product.

When irradiated, the molecules become crosslinked to provide an

even tougher and more abuse-resistant film.

Polyolefins are very stable

under long term storage conditions. They are able to withstand a

temperature of -60°F. or lower, making them ideal for packaging

frozen products. Due to the higher modulus of these materials,

the resultant stiffness and flatness make them an excellent

choice for high-speed automatic equipment. Finally, they produce

clean, non-corrosive films that will not leave char marks,

corrode equipment, discolor or relax and lose dimensional

stability.

There are a few limitations of

polyolefin films. These include the possible distortion of

non-rigid products because of high shrink tension. However, new

developments have lead to soft-shrink polyolefins. Some sealing

difficulty may also be encountered when running the material on

poorly maintained L sealers. It may not shrink well when

conveyed through tunnels with little air velocity or inadequate

temperature controls.

New technologies in

co-extrusion have made possible multilayer shrink films,

allowing the creation of products specifically tailored to meet

a packager's needs. High oxygen, moisture or aroma barriers and

solvent resistance are just a few possibilities utilizing this

technique. Special additives, blended in during production, are

also making possible antifog and antistatic films.

Linear low-density

polyethylenes (LLDPE) have contributed greatly to improved

abuse-resistance of shrink films. They've also reduced the

energy requirements of packaging lines by sealing and shrinking

at lower temperatures. Although usually available as a

monolayer product, LLDPE may find its greatest use in coextruded

films.

Co-extrusion allows the

incorporation of the positive aspects of various polymers into a

single multiply material. The toughness of LLDPE can be combined

with the excellent machinability of ethylene/propylene

copolymers to make a very strong film that can easily run on

high-speed automatic machinery

The 1980s have seen an

explosion in market demand for shrink films. They've become an

excellent choice for tamper-evident packaging, which is

increasingly important to the pharmaceutical and food

industries. Printing the surface with a company logo provides

even greater protection. Additional advantages have been derived

because film enhances the appearance of the package, creating a

premium image. Dairy products such as ice cream, cottage cheese

and yogurt have been quick to capitalize on these points.

With the recent introduction of

automatic collating equipment, shrink film can eliminate trays

or boxes, saving literally tens of thousands of dollars. The

rapid growth of the warehouse discount-club concept and its

demand that many items be sold in multiple units have greatly

increased the need for this type of unitized packaging. Contract

packagers, sheltered workshops and food processors have been

quick to accommodate this market.

Home entertainment applications

such as video cassettes and compact discs, and commercial

products such as floppy discs and computer software are among

the newest markets for shrink films. They've adopted films to

protect sensitive surfaces from microscopic contaminants--a

major hazard in their business--and to improve package

appearance. Antistatic films are a natural fit in this market.

Stable electrostatic

dissipative films, designed to package and protect circuit

boards, semiconductors and other static-sensitive products have

recently been introduced in the market place. These materials

are generally noncorrosive, transparent and compatible with the

polycarbonates that are used as "boards" in the electronic

industry. These are part of a new generation of specific

characteristic protective products that go far beyond the

traditional uses of shrinkable films.

The new barrier films are

another example of these highly sophisticated products. Barriers

can be engineered to contain the smell of naturally aromatic

products such as mothballs, or prevent off-odors from

contaminating sensitive consumer items such as chocolates and

beverages. Recent work even promises that they can help retain

important nutrients in foods during storage.

Another sophisticated new

product is a microwavable, antifog film that's currently being

used for consumer-sized packages of fresh-cut, trayed

vegetables. Its respiration rate is keyed to match that of the

product. Its antifog characteristic keeps the vegetables clearly

visible for maximum consumer impact --an important asset for

high-moisture, refrigerated products.

The markets for shrink film

will continue to expand as new technologies develop products

with more specialized characteristics. We're fast approaching

the day when "designer films" can be manufactured to meet the

most demanding requirements.

Stretch Films

By Bob W. Griggs Marketing

Manager Bemis Company, Incorporated

Stretch films can be stretched

to varying degrees depending upon the item or products being

unitized. Stretch films are applied to bundles, pallets of goods

and single items to provide product protection and maintain the

integrity of the items or loads.

Several different kinds of

stretch films are used. Low-density polyethylene, ethylene vinyl

acetate, linear low-density polyethylene and EVA-LLDPE blends

are dominant. LDPE films, introduced in the early '70s,

represent a small segment of the market today. EVA, a copolymer

stretch film, was introduced in the mid 1970s. The major

requirements for a good film include stretch, cling, strength

and stress retention--all of these properties are good to

excellent in this film group. LLDPE films, introduced in the

late 1970s, have very good to excellent properties of stretch,

strength and stress retention.

Film properties have a bearing

on how the unit is wrapped, stored, shipped and received at its

final destination.

Cling is the tackiness that

causes the film to stick to itself. Cling provides load

integrity by keeping the end of the film stuck to the wrap, and

causes the layers of film to laminate to each other on the load.

This layer-to-layer adhesion of the film holds the load

together.

There are several things that:

can affect the cling characteristics of a film. They are heat,

humidity, dust, dirt and the amount of stretch applied to the

film before it is applied to the unit or pallet. Film may have

adequate cling before it is stretched but not after.

The stiffness of a film also

has a bearing on its ability to stick to itself or maintain

adequate cling. Stiffer films are more difficult to stick to

themselves since they tend to pull away from the next layer.

Generally, softer films exhibit better cling characteristics.

Stretch is a film's ability to

elongate when a pulling force is applied. This pulling force is

applied either by the braking action on a stretch-wrapping

machine or manually. Generally as the percent of stretch

increases, the narrowing of width tear properties and the force

to the load increase while the gauge decreases. Most new

stretch-wrap equipment is designed to permit films to be used at

higher stretch levels while reducing neckdown and the force to

the load.

Puncture and tear resistance

are a measure of a film's ability to resist being punctured. If

punctured, as often happens in handling and shipping, it is a

measure of the film's ability to resist zippering to a point

where the film breaks.

Stress retention is the ability

of a film to retain the holding force that is applied to the

load or unit at the time it is being wrapped. All films relax

after they are put on the loads. The amount of relaxation

varies from film to film. The critical factor is that the

relaxation is not so great to cause the load to lose its

unitized integrity.

Yield means how much effective

stretch can be obtained from a film and still satisfy the other

requirements. The maximum yield obtained will vary depending on

such things as the weight, height and configuration of the load

as well as storage and shipping conditions.

Differential cling means that

one side of the film has more cling or tack the other side. This

permits the loads to have good load integrity or good

layer-to-layer adhesion with less cling on the outside of the

film. This low cling outside prevents the loads from blocking or

sticking to each other during storage and shipping.

In general, as the temperature

decreases, the cling characteristics of a film decrease. In

refrigerated and frozen food application there is a need for

good cling in temperature as low as 0°F. to -20°F. Some stretch

films maintain reasonable cling characteristics ill those

conditions.

Anti-static stretch film is

used in environments requiring a quick decay of static charges

generated during the wrapping) process. This property is

required in places such as aerosol packaging, paint

manufacturing, explosives and highly volatile environments.

Virtually all types, shapes:,

sizes and weights of unit loads are stretch wrapped both with

and without pallets or slip sheets. Stretch films are also used

to bundle many sizes, shapes and weights of goods which are

shipped as a bundle.

There are many ways to apply

stretch films to the pallets, units, bundles, etc. These methods

run all of the way from simple, inexpensive hand-held devices to

expensive fully automatic machines tied into fully automatic

palletizing, and conveyor systems. To get maximum benefit from

your system, the equipment must be properly designed and then

properly adjusted and maintained.

Load configuration is a factor

to consider when selecting the best film for the job. A film

that can adequately wrap a regular shaped load may not be strong

enough or have the puncture resistance required to handle an

irregularly shaped load. Even a regularly shaped load that is

smaller than the pallet will require a stronger film if the load

is to be tied to the pallet. The prestretch systems on the newer

equipment can lessen some of the load-shape problems.

The make-up of the load can

influence the type of film used as well as the force applied to

the load. A very light, fragile, low-density load that can be

easily crushed will require a different film type, gauge and

number of wraps applied to the unit than a heavier, rigid,

high-density load.

The type of equipment to apply

the film can have a bearing on the type of film used. New

machines are demanding of the films in terms of prestretch, the

system used, the speed of film application and forces applied to

the loads. All equipment changes have a bearing on the films

used.

You must test a film and its

application methods to select the proper film. Your products

must be wrapped on your equipment and shipped by your normal

methods to determine film effectiveness and cost efficiency.

These wrapping tests should be done with the film supplier

present during the wrapping.

DESICCANTS

Desiccant is used in packages

to protect products from damage caused by humidity and water

vapor. Desiccant is an extremely effective moisture absorbing

agent and is non-corrosive. It is inert, odorless, tasteless and

non-toxic. It meets Method II packaging standards described in

Mil P-116, which covers the basic requirements of military

packaging methods of preservation. Method II involves packaging

an item within a sealed water- and vapor-proof package,

enclosure. or container and providing desiccant inside to

prevent rust, corrosion or mildew. By enclosing desiccant, the

unit is held below 40% relative humidity for at least 18 months

to two years.

Desiccant is best utilized when

used in conjunction with sealed barrels, containers or barrier

bags. It is used effectively in the packaging of components and

instruments for the aerospace, computer and electronics

industries. Desiccant can also be used in packaging that does

not strictly conform to MIL Specs.

When properly applied,

desiccants can:

·

Prevent corrosion

and related damage to machine parts, optical equipment, tools,

cameras, medical instruments, and a variety of other products.

·

Prevent mildew

and rot in clothing. food products and documents.

·

Maintain the

activity of moisture-sensitive chemicals and the potency of

pharmaceuticals

·

Absorb moisture

that may lie on top of containers of chemicals or petroleum

products.

·

Enhance the

handling properties of hydroscopic materials, such as

maintaining powders and seeds in a free-flowing state

How do these tiny beads absorb

the moisture? The water vapor is attracted and held by the

microscopic pores and capillaries of the desiccant particles.

And, desiccant can be reactivated and reused many times, simply

by heating it in its own bag or package, at 250°F (120°C) for 16

hours.

Definition of Desiccant Unit

(MIL-D-3436D-3.3)

A desiccant unit is that

quantity of desiccant which will absorb at equilibrium with air

at 25°C at least the following quantities of water vapor:

(A) 3.00 grams at 20 percent

relative humidity and (B) 6.00 grams at 40 percent relative

humidity. In testing bagged desiccant an allowance will be made

for normal manufacturing variations. In connection with such

inspection testing, unit absorption capacity shall be at least:

(A) 2.85 grams at 20 percent relative humidity and (B) 5.70

grams at 40 percent relative humidity.

11.1 HUMIDITY INDICATOR CARDS

When using desiccant for long

term storage of products in a sealed barrier bag or sealed rigid

container, it is recommended to use Humidity Indicator cards or

plugs. These are simple means of indicating it the Desiccant

inside the bag or container is currently active. If it is not,

the container or bag should be opened, and the Desiccant

replaced.

Note: KEEP CONTAINERS TIGHTLY

SEALED TO PREVENT DESICCANT FROM ABSORBING MOISTURE

Aluminum Foil

By Flexible Packaging Division

Reynolds Metals Company

Of the raw materials commonly

available to produce flexible packaging, only aluminum foil can

provide an absolute barrier to gas, moisture and light

transmission. Further unlike other materials, these barrier

properties are relatively independent of gauge, particularly

when aluminum foil is combined with other materials. Aluminum

foil's pleasing metallic surface provides an upscale or quality

image to packaged products. Foil can be coated, laminated,

printed and embossed in a variety of ways.

By definition, aluminum foil is

any gauge or thickness less than 0.006 inches. Bare foil for

household and food service wrapping applications generally is

less than 0.001 inches in gauge. Gauges for converter foil,

which is combined with other materials to make flexible

packaging products, are generally less than 0.0005 inches; foils

currently being produced commercially go down to 0.0002 inches.

In certain applications, such as lidding stock for plastic or

aluminum containers, thicker foils of 0.001 to 0.003 inches may

be used in combination with coatings, extrusions and/or films to

provide a tough, high barrier , peelable lid.

Aluminum foil is produced from

direct chill (or DC) cast ingot or from continuously cast sheet.

In the former process, ingots produced by the DC method measure

15 or more feet in length, 6 feet or so in width, and up to 2

feet in thickness. These massive ingots are "soaked" at high

temperature, hot rolled to an intermediate gauge, then cold

rolled to foil gauges. In the continuously cast process, an

aluminum sheet varying from 1/4 to 1/2-inch in thickness is

produced from molten aluminum. This sheet is then cold rolled in

a series of rolling mill passes to the final foil gauge.

For flexible-packaging

applications, the aluminum used to produce foil is relatively

pure with only minute amounts of silicon, iron, copper,

magnesium or manganese added to produce desired properties. As

the metal passes through the various stages of rolling, it

work-hardens. This hardening can be relieved or tempered by

annealing--reheating the metal to a point where the rolled-in

stresses are relieved or eliminated by full recrystallization.

Foil usually receives at least two anneals--one approximately

midway through the rolling process and the second at finish

gauge.

During the production of

aluminum foil, in gauges below 0.001 inches, two webs of metal

are fed together, or doubled, into the rolling mill and rolled

to finish gauge simultaneously. They are then separated into two

single rolls for slitting, spooling, annealing and shipment to

the user packager. This practice produces a material that

presents a different appearance on either side of the foil. The

side that is next to the highly polished steel rolls of the mill

develops a bright, shiny finish. The other side, that next to

the other sheet of aluminum foil, develops a satin sheen finish

called matte. There is no major chemical or other difference

between the two surfaces of the metal as received by the

packager, but the two surfaces differ substantially in

appearance.

At the final gauge, the

aluminum foil is once again annealed to produce a final product

with the desired softness or temper and to prepare the surface

for its end use. Changing the final annealing practice can

result in a range of metal hardness, from intermediate temper to

"dead soft," required for most flexible-packaging applications.

In the case of converter foil used inflexible-packaging

applications, the final annealing step also removes residual

oils from the rolling operation and produces a clean surface

suitable for bonding to the inks, coatings and adhesives.

Aluminum foil is generally shipped in widths up to 72 inches in

rolls.

Aluminum Foil in Packaging

Aluminum foil is used in

flexible packaging as a plain metal or printed metal surface for

appearance purposes or for its barrier properties, formability

or other functional characteristics. Often both are combined in

the final package.

Foil is often used to convey

the look and feel of quality to a package. Many products utilize

foil's aesthetically pleasing appearance; classic examples

include cartons, labels and overwraps. Foil's appearance can be

further enhanced by its ability to be printed, through

rotogravure, flexographic, offset or letterpress processes. The

foil surface may first be treated to promote ink adhesion. After

printing it may be given a clear overcoat for protective

purposes or to provide desired machinability. It may be

partially printed to present a pleasing contrast or be

completely covered with ink.

When foil is to be used in a

packaging structure for its barrier properties, it is usually

necessary to protect the foil from rough handling, external

elements and/or the packaged product. A classic foil-bearing

structure used in packaging is

paper/polyethylene/foil/polyethylene. In this instance,

polyethylene protects the foil and provides a heat-sealing

medium. A whole host of other packaging structures are now in

the marketplace utilizing foil with films, paper, extrusion

coatings and laminations, etc.

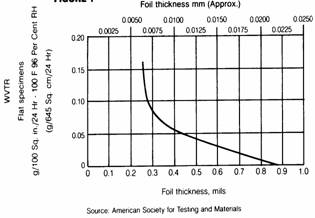

Below thicknesses of 0.0010

inches, foil may contain occasional minute openings called

pinholes. These are created during the rolling process and may

result from inclusions in the foil, particles in the rolling

fluids and a number of other factors. Actual pinhole counts can

vary substantially in thinner gauge foils, but generally will

tend to increase exponentially from virtually none at 0.001

inches to several hundred per square foot at ultra-thin gauges.

As a benchmark, one popular commercial specification states a

pinhole count of 65 per square foot or less at 0.000285 inches.

As a secondary measurement of pinholes, the rate of water vapor

or gas passing through bare foil will be a function of the

combined areas of pinholes present. A chart in ASTM standard

B479 shows typical water vapor transmission rates for 1145 plain

aluminum foil at 100°F and 96 percent relative humidity.

Typical water vapor

transmission rates for 1145 plain aluminum foil at 100°F and 96%

relative humidity.

While larger numbers of

pinholes may be expected in ultra-thin converter foils, the

moisture and gas transmission rates are still substantially

better than virtually any competing raw-material option.

A second physical concern in

the use of foil in flexible packaging is "flex cracking" which

can create the same type of barrier permeability as a pinhole.

However, by properly sandwiching the foil in a protective

structure, flex cracking can be significantly reduced or

eliminated. Shipping tests, vibration tests, drop tests, etc.,

are generally performed on developmental foil-bearing structures

where the prevention of flex cracking is of critical importance.

An even more complex issue than

pinholes or flex cracking is the protection of foil from

internal or external chemical attack. In a classic example, a

foil-bearing structure may be desirable to fully protect a

high-acid food product. However, if the high-acid food product

reaches the foil, the foil will react, producing hydrogen gas.

Similarly, highly basic materials penetrating to the foil

surface can act to corrode the foil, thus hampering its barrier

properties. Therefore, careful selection must be made to assure

that internal (or external) films, coatings and adhesives are

used so that the foil is protected from potentially damaging

elements.

As with the testing done for

flex cracking, a whole series of environmental and product

compatibility tests are performed on developmental foil-bearing

structures to ensure that a suitable barrier is maintained for

the expected shelf life of the product.

The unique functional

characteristics of aluminum foil and its aesthetically pleasing

appearance assure its continued and growing use as a packaging

material, particularly when combined with a rapidly increasing

choice of other materials in composite packaging structures. |