|

Thermoforming Processes

Thermoforming processes are

possible because thermoplastic sheets can be softened and

reshaped, and the new shape is retained when the material is

cooled. Most thermoplastic materials may be formed by this

process; however, acetals, polyamides, and fluorocarbons are not

usually thermoformed. Extruded, calendered, laminated, cast,

and blown films or sheet forms may be thermoformed.

Forcing a heated thermoplastic

material to take the shape of a mold by mechanical, air, or

vacuum pressure is common. Tooling costs are usually low, and

parts with large surface areas may be produced economically.

Prototypes and short runs are also practical. Although

dimensional accuracy is good, thinning is a problem in some part

designs.

Tooling can run from low-cost

plaster molds to expensive water-cooled steel molds, but the

most common tooling material is cast aluminum. Gypsum,

hardboard, pressed wood, cast phenolic resins, filled or

unfilled polyester or epoxy resins, sprayed metal, and steel

also may be used for molds.

One source dates thermoforming

back to the ancient Egyptians. They found that animal horns and

tortoise shells could be heated and formed into a variety of

vessels and shapes. In the United States, John Hyatt

thermoformed Celluloid sheets over wooden cores for piano keys.

Today, sheets and films may be

thermoformed by the basic techniques of straight vacuum forming,

drape forming, matched-mold forming, pressure-bubble plug-assist

vacuum forming, plug-assist vacuum forming, plug-assist pressure

forming, vacuum snap-back forming, pressure-bubble vacuum

snap-back forming, trapped-sheet contact-pressure forming, free

forming, and mechanical forming.

Items produced by thermoforming

include signs, light fixtures, ice-cube trays, ducts, drawers,

instrument panels, tote trays, housewares, toys, refrigerator

panels, transparent aircraft enclosures, and boat windshields.

Blister and skin packaging of products are familiar applications

of thermoforming. Replacement parts and hardware are examples of

items that are sometimes skin packaged. Skin packaging requires

no mold; the plastics film is simply formed over the product.

Cookies, pills and other products are commonly packaged by

blister packaging. Single portions of butter, jellies, and

other foods are sometimes packaged in blister packs.

1 STRAIGHT VACUUM FORMING

Vacuum forming is the most

versatile and widely used thermoforming process. Vacuum

equipment costs less than pressure or mechanical processing

equipment.

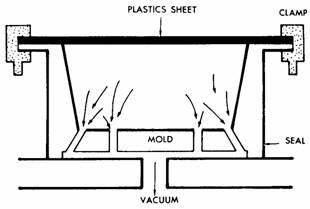

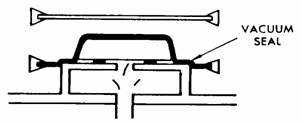

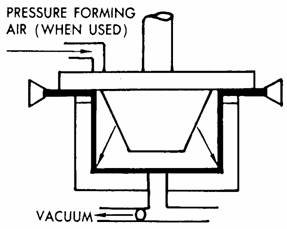

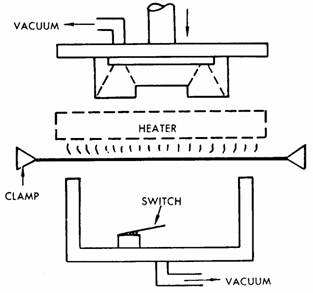

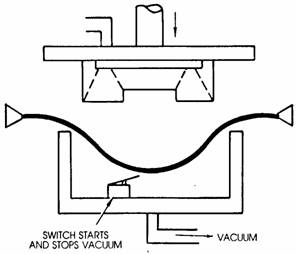

In straight vacuum forming, a

plastics sheet is clamped in a frame and heated. While the hot

sheet is rubbery, or in an elastic state, it is placed over a

female mold cavity. The air is removed from this cavity by

vacuum (Fig. 1) and atmospheric pressure (10 kPa) forces the hot

sheet against the walls and contours of the mold. When the

plastics has cooled, the formed part is removed, and final

finishing and decorating may be done, if necessary. Blowers or

fans are used to speed cooling. One disadvantage of

thermoforming is that formed pieces usually must be trimmed, and

the scrap must be reprocessed.

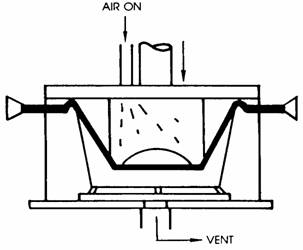

(A) A clamped and heated

plastic sheet is forced down into the mold by air pressure after

a vacuum is drawn in the mold. (Atlas Vac Machine Co.)

(B) Plastics sheet cools as it

contacts the mold. (Atlas Vac Machine Co.)

(C) Areas of the sheet that

touched the mold last are the thinnest. (Atlas Vac Machine Co.)

Fig. 1 Straight vacuum forming.

Most vacuum systems have a

surge tank to ensure a constant vacuum of 500 to 760 mm of

mercury. Superior parts are formed by quickly applying the

vacuum before any portion of the sheet has cooled. Slots are

more desirable and efficient than holes in allowing the air to

be drawn from the mold. Slots or holes should be smaller than

0.65 mm [0.025 in.] in diameter to avoid surface blemishes on

the formed part. A hole or slot should be placed in all low or

unconnected portions of the mold. If this is not done, air may

be trapped under the hot sheet with no way to escape. Unless

they are collapsible, molds should include a 2 to 7 degree angle

(draft) for easy part removal.

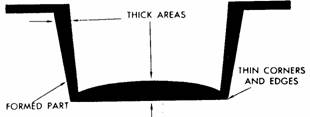

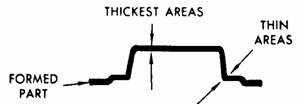

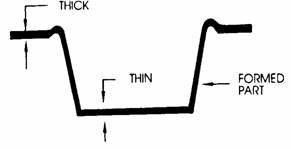

Thinning at the upper edges of

a part is a disadvantage in using relatively deep female molds.

Thinning is caused by the hot plastics sheet first being drawn

to the center of the mold. Sheeting at the edges of the mold

must stretch the most and thus becomes the thinnest portion of

the formed item. If preprinted flat sheets are formed, thinning

must be kept in mind when trying to compensate for distortion

during forming. Straight vacuum forming is limited to simple,

shallow designs, and thinning will occur often in corners.

The draw or draw ratio of a

female mold is the ratio of the maximum cavity depth to the

minimum span across the top opening. For high-density

polyethylene, the best results are achieved when this ratio does

not exceed 0.7:1. Thermoforming equipment and dies are

relatively inexpensive.

2 DRAPE FORMING

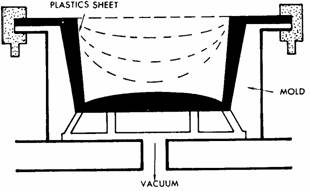

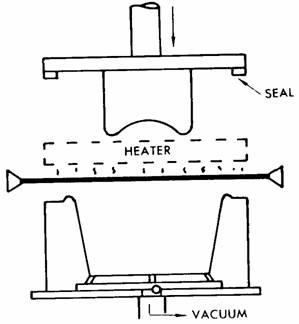

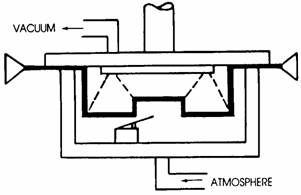

Drape forming (incorrectly

called mechanical forming) is similar to straight vacuum forming

except that after the plastics is framed and heated, it is

mechanically stretched over a male mold. A vacuum (actually, a

pressure differential) is applied that pulls the hot plastics

against all portions of the mold (Fig. 2). The sheet touching

the mold remains close to its original thickness. Side walls

are formed by the material draping between the top edges of the

mold and the bottom seal area at the base. When the plastics

has cooled, it is removed for trimming or post-processing, if

needed. Mark-off (marks from the mold) is on the inside of the

product while such marks appear on the outside of the part in

straight vacuum forming.

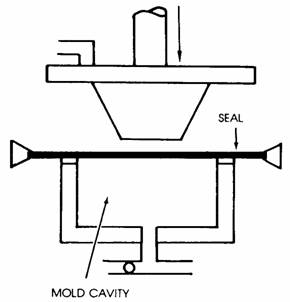

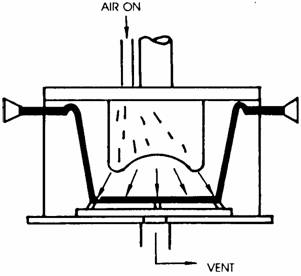

(A) Clamped heated plastics may

be pulled over the mold, or the mold may be forced into the

sheet.

(B) Once the sheet has formed a

seal around the mold, a vacuum is drawn to pull the plastics

sheet tightly against the mold surface.

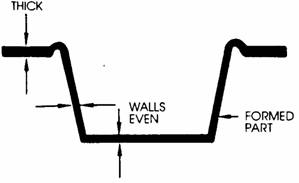

(C) Final wall thickness

distribution in the molded part.

Fig. 2. Principle of drape

forming plastics. (Atlas Vac Machine Co.)

It is possible to drape-form

items with a depth to diameter ratio of nearly 4:1. High draw

ratios are possible with drape forming, however, this technique

is also more complex. Male molds are easy to make and, as a

rule, cost less than female ones, but male molds are more easily

damaged.

Drape forming has also been

used to form a hot plastics sheet over male or female molds by

gravitational forces alone. Female molds are preferred for

multicavity forming because there must be more spacing if male

molds are selected.

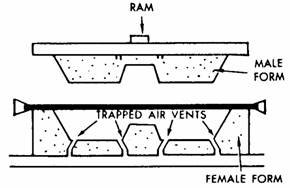

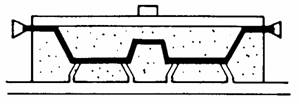

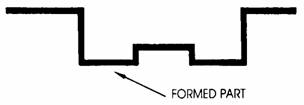

3 MATCHED-MOLD FORMING

Matched-mold forming is similar

to compression molding. A heated sheet is trapped and formed

between male and female dies that may be made of wood, plaster,

epoxy, or other materials (Fig. 3). Accurate parts with

close-tolerances may be quickly produced in costly water-cooled

molds. Very good molded detail and dimensional accuracy can be

obtained with water-cooled molds, including lettering and

grained surfaces. There is mark-off on both sides of the

finished product; therefore, mold dies must be protected from

scratches or damage because such defects would be reproduced by

the thermoplastic materials. A smooth-surfaced mold should not

be used with polyolefins because air may be trapped between the

hot plastics and a highly polished mold. Sandblasted mold

surfaces are usually used for these materials.

(A) The heated plastics sheet

may be clamped over the female die, as shown, or draped over the

mold form.

(B) Vents allow trapped air to

escape as the mold closes and forms the part.

(C) Distribution of materials

in the product depends on the shapes of the two dies.

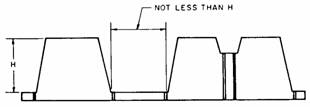

(D) Male mold forms must be

spaced at a distance equal, to or greater than their height or

webbing may occur.

Fig. 3. Principle of

matched-mold forming. (Atlas Vac Machine Co.)

4 PRESSURE-BUBBLE PLUG-ASSIST

VACUUM FORMING

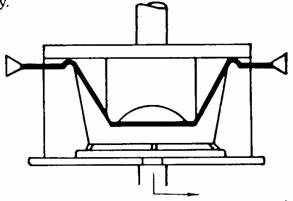

For deep thermoforming,

pressure-bubble plug-assist vacuum forming is an important

process. By this process, it is possible to control the

thickness of the formed article. The item may have uniform

thickness or the thickness may be varied.

Once the sheet has been placed

in the frame and heated, controlled air pressure creates a

bubble (Fig. 4). This bubble stretches the material to a

predetermined height, usually controlled by a photocell. The

male plug assist is then lowered forcing the stretched stock

down into the cavity. The male plug is normally heated to avoid

chilling the plastics prematurely. The plug is made as large as

possible so the plastics is stretched close to the final shape

of the finished product. Plug penetration should be from 70 to

80 percent of the mold cavity depth. Air pressure is then

applied from the plug side while at the same time a vacuum is

drawn on the cavity to help form the hot sheet. For many

products, vacuum alone is used to complete formation of the

sheet. In Figure 7-4, both vacuum and pressure are applied

during the forming process. The female mold must be vented to

allow trapped air to escape from between the plastics and the

mold.

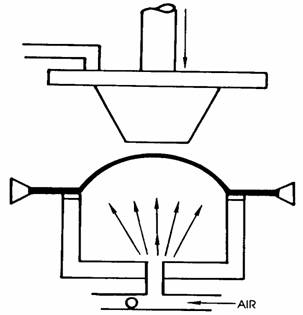

(A) The plastics sheet is

heated and sealed across the mold cavity.

(B) Air is introduced, blowing

the sheet upward into an evenly stretched bubble.

(C) A plug shaped roughly to

the cavity contour presses downward into the bubble, forcing it

into the mold.

(D) When the plug reaches its

lowest point, vacuum is drawn to pull the plastics against the

mold walls. Air may be introduced from above to aid forming.

Fig. 4. Pressure-bubble

plug-assist vacuum forming. (Atlas Vac Machine Co.)

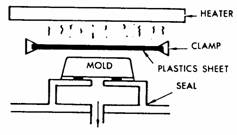

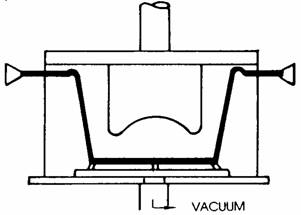

5 PLUG-ASSIST VACUUM FORMING

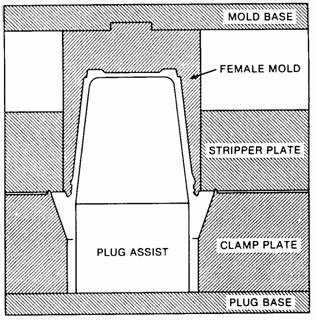

To help prevent corner or

periphery thinning of cup- or box-shaped articles, a plug assist

is used to mechanically stretch and pull additional plastics

stock into the female cavity (Fig. 5). The plug is normally

heated to just below the forming temperature of the sheet

stock. The plug should be from 10 to 20 percent smaller in

length and width than the female mold. Once the plug has forced

the hot sheet into the cavity, air is drawn from the mold,

completing the formation of the part. The plug design or shape

determines the wall thickness, as shown in cross-section in

Figure 5D.

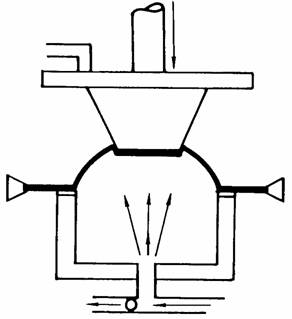

(A) Heated, clamped plastics

sheet is positioned over mold cavity.

(B) A plug, shaped roughly like

the mold cavity, plunges into the plastics sheet to pre-stretch

it.

(C) When the plug reaches the

limit of its travel, a vacuum is drawn in the mold cavity.

(D) Areas of the plug touching

the sheet first form thickened areas due to chilling effect.

Fig. 5. Plug-assist vacuum

forming. (Atlas Vac Machine Co.)

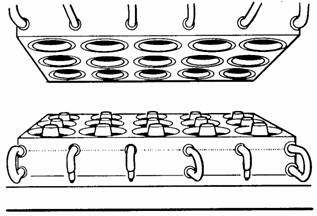

Plug-assist vacuum and pressure

forming allows deep drawing, and permits shorter cooling cycles

and better control of wall thickness. Close temperature control

is needed, however, and the equipment is more complex than

straight vacuum forming (Fig. 6).

(A) Clamp layout

(B) RAM part clamps.

Fig. 6. Restricted-area molding

(RAM), with individual part clamps build into the mold. This

helps to control material draw and reduces draw ratio. (Brown

Machine Co.)

6 PLUG-ASSIST PRESSURE

FORMING

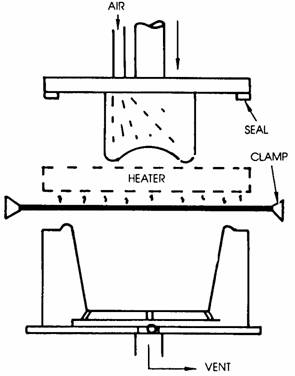

Plug-assist pressure forming is

similar to plug-assist vacuum forming in that the plug forces

the hot plastics into the female cavity. Air pressure applied

from the plug forces the plastics sheet against the walls of the

mold (Fig. 7).

(A) Heated, clamped sheet is

positioned over the mold cavity.

(B) As the plug touches the

sheet, air is allowed to vent from beneath the sheet.

(C) As the plug completes its

stroke and seals the mold, air pressure is applied from the plug

side, forcing the plastics against the mold.

(D) Plug-assist pressure

forming is capable of producing products with uniform wall

thickness.

Fig. 7. Plug-assist pressure

forming . (Atlas Vac Machine Co.)

7 VACUUM SNAP-BACK FORMING

In vacuum snap-back forming,

the hot plastics sheet is placed over a box and a vacuum is

drawn that causes a bubble to be forced into the box (Fig. 8).

A male mold is lowered and the vacuum in the box is released,

causing the plastics to snap-back around the male mold. A

vacuum may also be drawn in the male mold to help pull the

plastics into place.

(A) Plastics sheet is heated

and sealed over the top of the vacuum box. (Atlas Vac Machine

Co.)

(B) Vacuum is drawn beneath the

sheet, pulling it into a concave shape. (Atlas Vac Machine Co.)

(C) The male plug is lowered

and a vacuum drawn through it. At the same time, vacuum beneath

the sheet is vented. (Atlas Vac Machine Co.)

(D) External deep draws can be

obtained with this process to form luggage, auto parts, and

other items. (Atlas Vac Machine Co.)

Fig. 8. Vacuum snap-back

forming. (Atlas Vac Machine Co.)

Vacuum snap-back forming allows

complex parts with recesses to be formed.

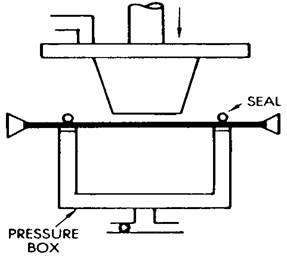

8 PRESSURE-BUBBLE VACUUM

SNAP-BACK FORMING

As the name implies, the sheet

is heated and then stretched into a bubble shape by air pressure

(Fig. 9). The sheet pre-stretches about 35 to 40 percent. The

male mold is then lowered. A vacuum is applied to the male mold

while air pressure is forced into the female cavity. This

causes the hot sheet to snap-back around the male mold.

Mark-off is on the male mold side.

(A) Heated plastics sheet is

clamped and sealed across a pressure box.

(B) Air pressure is introduced

beneath the sheet, causing a large bubble to form.

(C) A plug is forced into the

bubble, while air pressure is maintained at a constant level.

(D) Air pressure beneath the

bubble and a vacuum at the plug side create a uniform draw.

Fig. 9. Pressure-bubble vacuum

snap-back forming. (Atlas Vac Machine Co.)

Pressure-bubble vacuum

snap-back forming allows deep drawing and the formation of

complex parts, but the equipment is complex and costly.

9 TRAPPED-SHEET CONTACT HEAT

PRESSURE FORMING

This process is like straight

vacuum forming except that air pressure and a vacuum assist may

be used to force the hot plastics into a female mold. Figure

7-10 shows the steps of this process.

(A) A flat, porous plate allows

air to be blown through its face.

(B) Air pressure from below and

a vacuum above force the sheet tightly against the heated plate.

(C) Air is blown through the

plate to force the plastics into the mold cavity.

(D) After forming, additional

pressure may be exerted.

Fig. 10. Trapped-sheet

contact-heat pressure forming. (Atlas Vac Machine Co.)

10 FREE FORMING

In free forming, air pressures

of over 2.7 MPa may be used to blow a hot plastics sheet through

the silhouette of a female mold (Fig. 11). The air pressure

causes the sheet to form a smooth bubble shaped article. A stop

may be used to form special contours in the bubble. Skylight

panels and aircraft canopies are well-known examples of this

technique.

(A) Basic setup.

(B) Air injection

(C) Examples of free-form

shapes that can be obtained with various openings. (Rohm & Haas

Co.)

Fig. 11. Free forming of

plastics bubbles.

11 MECHANICAL FORMING

In mechanical forming, no

vacuum or air pressure is used to form the part. It is similar

to matched molding; however, close-fitting matched male and

female molds are not used.

This process is sometimes

classified as a fabrication or post-forming operation. The

forming process may make use of simple wooden forming jigs to

give the desired shape using ovens, a strip heater, or heat guns

for the heat source. Flat stock may be heated and wrapped around

cylindrical shapes or stock may be heated in a narrow strip and

bent at right angles. Tubes, rods, and other profile shapes may

be mechanically formed.

12 PLASTIC PROCESSING

12.1

Injection molding

12.1.1 Process: Similar to

die casting of metals, a thermoplastic molding compound is

heated to plasticity in a cylinder at a controlled temperature

and then forced under pressure through sprues runners, and gates

into a cool mold; the resin solidifies rapidly, the mold is

opened, and the parts ejected; with certain modifications,

thermosetting materials can be used for small parts.

12.1.2 Advantages:

Extremely rapid production rate and hence low cost per part,

little finishing required; excellent surface finish; good

dimensional accuracy; ability to produce a variety of relatively

complex and intricate shapes.

12.1.3 Limitations: High

tool and die costs; high scrap loss; limited to relatively small

parts; not practical for small runs.

12.2

Cut extrusions

12.2.1 Process:

Thermoplastic molding powder is fed through a hopper to a

chamber where it is heated to plasticity and then driven,

usually by a rotating screw, through a die having the desired

cross section; extruded lengths are either used as is or cut

into sections; with modifications, thermosetting materials can

be used.

12.2.2 Advantages: Very low

tool cost; material can be placed where needed; great variety of

complex shapes possible; rapid production rate.

12.2.3 Limitations: Close

tolerances difficult to achieve; openings must be in direction

of extrusion; limited to shapes of uniform cross section (along

length).

12.3 Sheet moldings

(thermoforming) VACUUM FORMING

12.3.1 Process:

Heat-softened sheet is placed over a male or female mold; air is

evacuated from between sheet and mold, causing sheet to conform

to contour of mold. There are many

modifications, including vacuum

snapback forming, plug-assist, drape forming etc..

12.3.2 Advantages: Simple

procedure; inexpensive; good dimensional accuracy; ability to

produce large parts with thin sections.

12.3.3 Limitations: Limited

to parts of low profile.

12.4 Sheet molding

(thermoforming) BLOW OR PRESSURE FORMING

12.4.1 Process: The reverse

of vacuum forming in that positive air pressure rather than

vacuum is applied to form sheet to mold contour.

12.4.2 Advantages: Ability

to produce deep drawn parts; ability to use sheet too thick for

vacuum forming; good dimensional accuracy; rapid production

rate.

12.4.3 Limitations:

Relatively expensive; molds must be highly polished.

12.5 Sheet molding

(thermoforming) MECHANICAL FORMING

12.5.1 Process: Sheet metal

equipment (presses benders, rollers creasers. etc.) forms heated

sheet by mechanical means. Localized heating is used to bend

angles; where several bends are required, heating elements are

arranged in series.

12.5.2 Advantages: Ability

to form heavy and/or tough materials; simple; inexpensive;

rapid production rate.

12.5.3 Limitations: Limited

to relatively simple shapes.

12.6

Blow moldings

12.6.1 Process: An extruded

tube (parison) of heated plastics within the two halves of a

female mold is expanded against the sides of the mold by air

pressure; the most common method uses injection molding

equipment with a special mold.

12.6.2 Advantages: Low tool

and die cost; rapid production rate; ability to produce

relatively complex hollow shapes in one piece.

12.6.3 Limitations: Limited

to hollow or tubular parts; wall thickness difficult to control.

12.7

Slush rotational dip

castings

12.7.1 Process: Powder

(polyethylene) or liquid material (usually vinyl plastisol or

organosol) is poured into a closed mold, the mold is heated to

fuse a specified thickness of material adjacent to mold surface,

excess material is poured out, and the semifused part is placed

in an oven for final curing. A variation, rotational molding,

provides completely enclosed hollow parts.

12.7.2 Advantages: Low cost

molds, relatively high degree of complexity; little shrinkage.

12.7.3 Limitations:

Relatively slow production rate; choice of materials limited.

12.8

Compression moldings

12.8.1 Process: A partially

polymerized thermosetting resin, usually pre-formed, is placed

in a heated mold cavity; mold is closed, heat and pressure

applied, and the material flows and fills mold cavity; heat

completes polymerization and mold is opened to remove hardened

part. Method is sometimes used for thermoplastics, e.g., vinyl

phonograph records; in this operation, the mold is cooled before

it is opened.

12.8.2 Advantages: Little

waste of material and reduced finishing costs due to absence of sprues, runners, gates, etc.; large, bulk parts possible.

12.8.3 Limitations:

Extremely intricate parts involving undercuts, side draws, small

holes, delicate inserts etc., not practical, extremely close

tolerances difficult to achieve.

12.9

Transfer moldings

12.9.1 Process: Used

primarily for thermosetting materials, this method differs from

compression molding in that the plastic is 1) first heated to

plasticity in a transfer chamber, and 2) fed, by means of a

plunger, through sprues, runners, and gates into a closed mold.

12.9.2 Advantages: Thin

sections and delicate inserts are easily used; flow of material

is more easily controlled than in compression molding; good

dimensional accuracy; rapid production rate.

12.9.3 Limitations: Molds

are more elaborate than compression molds and hence more

expensive; loss of material in cull and sprue; size of parts

somewhat limited.

12.10 Reinforced plastics

moldings CONTACT

12.10.1 Process: The

lay-up, which consists of a mixture of reinforcement (usually

glass cloth or fibers) and resin (usually thermosetting), is

placed in mold by hand and allowed to harden without heat or

pressure.

12.10.2 Advantages: Low

cost; no limitations on size or shape of part.

12.10.3 Limitations: Parts

are sometimes erratic in performance and appearance; limited to

polyesters epoxies and some phenolics.

12.11 Reinforced plastic

moldings VACUUM BAG

12.11.1 Process: Similar to

contact except a flexible polyvinyl alcohol film is placed over

lay-up and a vacuum drawn between film and mold (about 82 kPa).

12.11.2 Advantages: Greater

densification allows higher glass contents, resulting in higher

strengths.

12.11.3 Limitations:

Limited to polyesters epoxies and some phenolics.

12.12 Reinforced plastic

moldings PRESSURE BAG

12.12.1 Process: A

variation of vacuum bag in which a rubber blanket (or bag) is

placed against film and inflated to apply about 350 kPa.

12.12.2 Advantages: Allows

greater glass contents.

12.12.3 Limitations:

Limited to polyesters epoxies and some phenolics.

12.13 Reinforced plastic

moldings AUTOCLAVE

12.13.1 Process: The

vacuum-bag setup is simply placed in an autoclave with hot air

at pressures up to 1.38 MPa.

12.13.2 Advantages: Better

quality moldings.

12.13.3 Limitations: Slow

rate of production.

12.14 Reinforced plastic

moldings MATCHED DIE

12.14.1 Process: A

variation of conventional compression molding, this process uses

two metal molds which have a close-fitting telescoping area to

seal in the resin and trim the reinforcement; the

reinforcement, usually mat or pre-form is positioned in the

mold, a pre-measured quantity of resin is poured in, and the

mold is closed and heated; pressures generally vary between 1.04

and 2.75 MPa.

12.14.2 Advantages: Rapid

production rates; good quality and excellent reproducibility;

excellent surface finish on both sides; elimination of trimming

operations; high strength due to very high glass content.

12.14.3 Limitations: High

mold and equipment costs; complexity of part is restricted; size

of part limited.

12.15 Reinforced plastic

moldings FILAMENT WOUND

12.15.1 Process: Glass

filaments, usually in the form of rovings, are saturated with

resin and machine wound onto mandrels having the shape of

desired finished part; finished part is cured at either room

temperature or in an oven, depending on resin used and size of

part.

12.15.2 Advantages:

Provides precisely oriented reinforcing filaments; excellent

strength-to-mass ratio; good uniformity.

12.15.3 Limitations:

Limited to shapes of positive curvature; drilling or cutting

reduces strength.

12.16 Reinforced plastic

moldings SPRAY MOLDING

12.16.1 Process: Resin

systems and chopped fibers are sprayed simultaneously from two

guns against a mold; after spraying, layer is rolled flat with a

hand roller. Either room temperature or oven cure.

12.16.2 Advantages: Low

cost; relatively high production rate; high degree of complexity

possible.

12.16.3 Limitations:

Requires skilled workers; lack of reproducibility.

12.17

Castings

12.17.1 Process: Plastics

material (usually thermosetting except for the acrylics) is

heated to a fluid mass, poured into mold (without pressure),

cured, and removed from mold.

12.17.2 Advantages: Low

mold cost; ability to produce large parts with thick sections;

little finishing required; good surface finish.

12.17.3 Limitations:

Limited to relatively simple shapes.

12.18

Cold moldings

12.18.1 Process: Method is

similar to compression molding in that material is charged into

a split, or open, mold; it differs in that it uses no heat -

only pressure. After the part is removed from mold, it is

placed in an oven to cure to final state.

12.18.2 Advantages: Because

of special materials used, parts have excellent electrical

insulating properties and resistance to moisture and heat; low

cost; rapid production rate.

12.18.3 Limitations: Poor

surface finish; poor dimensional accuracy; molds wear rapidly;

relatively expensive finishing; materials must be mixed and used

immediately.

|