|

Materials

1.1

Structural elements

A corrugated

box consists of two structural elements: the facings

(linerboard) and the fluting structure (corrugated medium).

Linerboard can be of several types.

1.1.1 Types

of Liner

Fourdrinier

Kraft Liner - "Fourdrinier" is the name of the man who invented

the machine on which the liner is made. "Kraft", the German word

for strength, is attributed to the strength applied to pulp,

paper, or paperboard produced from wood fibers by the sulfate

process. The Kraft liner is produced from a high percentage of

pinewood (softwood) fibers which imparts toughness as softwood

fibers are longer in length than hardwood fibers and allows for

a greater interlocking effect. The sheet is made by randomly

orienting the fibers and is formed on a traveling endless wire

screen which may also be vibrated. This Kraft liner provides the

best Tear and Tensile strength properties available in the

paperboard industry today. The liner is used to package products

in all areas of the corrugated packaging and is widely known as

one of the best packaging materials available.

Cylinder

Recycled Linerboard - This liner is often called "Jute," a

misleading term since it never contains any jute fiber. The

correct reference name is "test liner" and is produced from

reclaimed fibers on a cylinder-type paper machine. Although test

liner often contains a certain proportion of virgin kraft fiber,

it is inherently weaker than kraft linerboard. Due to the

recycled fiber content, the basis weight of the recycled liner

may be increased to meet the Mullen test of comparable virgin

linerboard. The advantages of test liner is that it is

generally less expensive to manufacture than kraft liner and it

is an environmentally sound means of recycling used packaging.

The two recycled materials most often used to provide a furnish

for the test liner are:(1) double line kraft clippings: and(2)

old corrugated containers.

Double lined

kraft clipping(DLK) waste is comprised of the trim and cutouts

generated during the process of manufacturing corrugated boxes.

It is highly desirable due to its cleanliness and consistency.

Old

corrugated container(OCC) waste is generated by collecting

corrugated boxes from stores, supermarkets, etc. after they have

been emptied. Although OCC material requires extensive

cleaning, it is an important source of recycled fiber throughout

the world.

Kraft

linerboard can have up to 25% recycled fiber. The average

recycled content of linerboard in 1990 was about 12%. There is

a problem citing figures. The numbers change rapidly and the

recycled fiber content of containerboard is increasing each

year.

Schrenz - In

many parts of the world, there are packaging economies which

lack extensive forests of softwood or the foreign exchange to

import softwood fiber, In these countries the use of recycled

fibers means "whatever fiber is locally available," down to and

including "old newspaper." The "Schrenz" is of German origin

but is understood elsewhere. Liners of this kind are often seen

in the US in boxes bringing in exports. Unless colored or

covered by a layer of other fiber deposited on the surface from

a secondary headbox, the sheet has a gray appearance and is

inferior in strength characteristics.

1.1.2 Types

of Medium

Semichemical

- This type consists of hardwood fibers made by a neutral

sulfite or comparable process. "Semichemical" refers to the fact

that hardwoods are difficult to defiber, and so the defibering

process is partly mechanical and partly chemical. This variety

is the most prevalent in the US. Appearance and other

characteristics may vary, depending on the species of wood, the

method of cooking and washing, and other production techniques.

Most of this is produced on Fourdrinier machines. Some is

produced on other forming machines. All methods of forming can

make a good medium; quality depends on furnish and stock

preparation, not on formation. Semichemical medium is "virgin"

if 75% or more of the furnish is new fibers. All-hardwood sheets

are rare since the addition of some softwood, although recycled,

is desirable to give better "runnability."

Bogus - This

type of medium is based on recycled kraft waste, generally old

corrugated. The term "bogus" is unjustified since it denotes

imitation which is incorrect. When properly made, bogus can be

of high quality and equivalent to semichemical medium.

Kraft - The

use of kraft medium is limited to situations when high tear or

puncture resistance is needed. The total consumption for this

purpose is so small that the equivalent weight kraft liner board

is substituted, but it doesn't corrugate well.

Other - This

covers any fibers not described in the foregoing paragraphs and

corresponds to the comments made under the "Schrenz" heading

for liner board.

In the US

and Canada, freight rule requirements have led to the

development of standard grades of linerboard and medium. For

linerboard, "standard" is defined in terms of basis weight and

burst strength, based on kraft facings. Caliper is not specified

for liners used to make corrugated; mills allow caliper to

"float." This permits them to run their machines to optimize

other and more important characteristics.

For

corrugated medium, "standard" is defined in terms of caliper and

basis weight. The rule calls for a minimum caliper of 0.009

inch (2.29 mm) and a minimum basis weight of 26 pounds per

thousand square feet (lb./MSF) (127 g/m2).

medium is thus referred to in the trade as "nine point".

Information

on the different properties that medium can add to the board

combination can be found in the "Compression Guideline"

available from the address and phone number on the bottom of the

page.

1.2 Combined

Board Structures

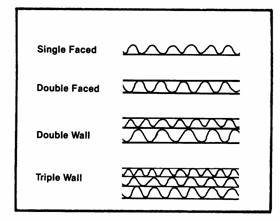

There are

four basic combined board structures in the corrugated industry;

single faced, single wall (double faced), double wall, and

triple wall.

Single faced

corrugated is made up of a single corrugated medium and a

liner. It is mainly used as a protective wrap.

Single wall

or double faced board is made up of a single corrugated medium

between two liners. The medium material can be formed into any

flute height depending on the properties desired of the board or

the end use of the container. It is used in 90% of all

corrugated containers. It can be used to make box liners, pads,

shells, tubes, partitions, die cut interior forms and display

units. single wall lends itself to use in automated high speed

packaging lines because of easy bending and lower board memory

and relative dimensional stability. The advantages of this

material that it can have tailored construction to meet package

use and requirements. It has superior die cut workability and

dimensional precision and high strength to material ratio.

Double wall

is made up of three liner elements and two corrugated mediums.

the medium, like single wall, can be formed into any combination

of flute configurations. The combination of fluting and the

weights of the liners used is determined by the use of the board

or the demands to be made on the container in performance. It

is used in packaging of heavy products, bulk material, items

which require the extra strength and puncture resistance. The

high compression strength and flexural stiffness in relation to

single wall, make the material outstanding for inner packing,

corner posts and bulge resistant applications.

For reasons

of economy, symmetrical flute constructions in double wall

boards, such as AA or CC are infrequently used. Mainly for

production flexibility, corrugated box plants run both fluting

rollers (A, B, and/or C) on the corrugator to produce two

different flutes in the final sheet.

Triple wall

is the most complex and least used of the three. It consists of

4 liners and 3 corrugated mediums. Using various strength liners

and mediums, this material can be tailored to any packaging

demand. It is used where maximum stack strength and sidewall

strength is required.

1.3 Flute

Orientation

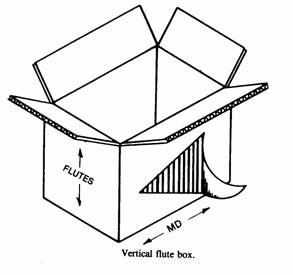

Boxes are

normally made with the flute direction running vertically.

This provides better stacking strength on the vertical

direction.

For a few

commodities, shipping containers may be made with the flutes

running horizontally.

Such boxes

are usually end-opening. They are stacked, stored or shipped

laying on their side because this is the direction of their

greatest strength.

1.4 Flute

Structure

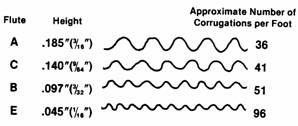

There are

four basic fluted board heights available in conventional

corrugated board...A, B, C, and E flutes.

2.

Corrugated Manufacturing

2.1

Formation

The

corrugator machine flutes the medium, places liquid starch on

the peaks of the flutes, then combines it with the liners into a

continuous web of combined board. The material is then passed

through hot "irons" causing the water to be dried out of the

starch gluing the liners and medium together. Once combined the

web passes through a slitter/scorer where the web is cut and

scores are applied in the machine direction. The last operation

on the corrugator is the cut off knife where the slit/scored

web is cut into blanks.

2.1.1

Die-cut

Corrugated

that is to be die-cut does not get scored on the corrugator and

is printed before being die-cut. Some die-cutting machines can

print the corrugated before die-cutting it, others need the

corrugated to be printed on a separate machine. The process is

simple, a plain pad of corrugated is feed into a machine where a

die (like a cookie cutter) stamps out the item. The die can

either be rotary or flat depending the item's size and quantity

being run. The die can cut, slit and scores all at the same

time depending on what type of knife or rule is used. The

cutting die's tooling cost is based on how many inches of knife

or rule is used to make the die and the type of die (i.e. rotary

dies are more expensive than flat dies).

2.1.2 Non

Die-cut

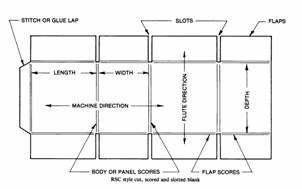

Non die-cut

items are run on machines that can be modified for each order

and do not require tooling. The most common example is a RSC

(regular slotted container) below.

The flap

scores are put on by the slitter/scorer at the corrugator. The

resulting blank is next processed on a printer-slotter, which

prints, puts in the panel or body scores, and slots the box.

3.

General Styles

Box

dimensions are always inside dimensions (I.D.) and are stated in

sequence of Length x Width x Depth (LxWxD). The first two

dimensions mentioned are always considered the size of the

opening.

Common

drawings of box styles can be found in the format drawings at

the end of this section or in the Fibre Box Handbook which can

be ordered through PPO order or call Corporate Packaging

Programs at the number on the bottom of this page.

4.

Design Concepts

4.1 Optimum

Design

Every

Packaging Engineer endeavors to arrive at a design which will be

"optimum." The question is, optimum with respect to what? At

what point does the process of optimizing begin?

The answers

to these questions involve an understanding of what the function

of the package is to be, the conditions and circumstances of its

use, and balance between sometimes conflicting goals.

Circumstances also dictate where the optimizing process begins.

If the package is designed by the Packaging Engineer, the option

of selecting the best material will most likely not be part of

the process. The Packaging Engineer usually has neither the

means to control that process nor the information needed to

implement it. Therefore, the more collaboration there is between

the Packaging Engineer and the package maker, the earlier in the

chain the process of optimizing can start.

4.2

Constraints

The number

of choices and options available is large, but only within

certain constraints. Regulations, such as freight rules, the

Hazardous Materials Regulations, and specification requirements

may mandate limits with respect to box size, test criteria,

contents weight, board combination, etc. Your

equipment and the storage, handling and shipping environment

must be considered.

The nature,

shape and fragility of the product help to define what is

optimum.

Before going

on to the specifics, it should be clear that it is not suggested

that all steps outlined in this section are part of the design

process of every package.

4.3 Board

Structure

The basic

fact to remember is the way corrugated functions as a structure

under load.

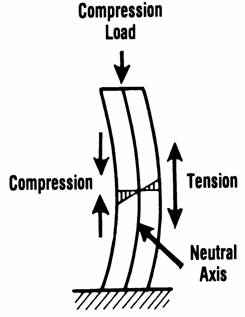

When a

corrugated column is under load, the structure bends until it

buckles. In a box with contents this bending generates

compression stresses in the inside liner, while the outside

liner is in tension.

Therefore,

if the board combination is unbalanced, the heavier or rather,

the stiffer liner (the two usually go together) should be the

inside liner. For printing it is best to have the heaviest on

the outside.

On double

wall board there is an additional factor to be considered. The

center liner, even if it is not commonly at the exact center -

because most double wall construction do not have identical

flute contours - is near the neutral axis where the compression

contribution is minimal. Therefore, the optimum board

combination is the one where the inside liner is the stiffest,

the weakest liner is in the center, and the second stiffest

liner is on the outside. The center liner needs only to be

strong enough to hold the flute structure in place. The more

weight per stiffness one can concentrate on the inside, the

better, with due regard for other characteristics, of course. In

other words, when it comes to double wall constructions, one can

juggle board combinations at will, the only constraint being

that the minimum combined weight of facings must comply with the

freight rules.

Schematic of

stresses in a compressed corrugated panel.

Along the

same lines, a thinner column bends more easily than a thicker

one. Therefore, all things being equal, any step towards

maximizing caliper is a step towards optimizing the box. The

chief mechanism for achieving this is the flute structure.

In single

wall boards the progression from best to worst in (top to

bottom) compression is from A to C to B, except that caliper

loss sustained in fabrication tends to negate the advantage of

A-flute, a fact of increasingly greater importance as medium

becomes softer. For general good performance with regular 26 lb.

medium, C flute is better, combining as it does the advantages

of B flute with those of A flute.

4.4 Die Cut

Holes

A box is

only as strong as its weakest column. Die cut holes, slots and

slits are normally the weakest part of any corrugated shipping

container. The removal of material, or crushing of the

corrugated structure, causes the surrounding area to take up the

additional stress causing it to fail before the rest of the

container. This is multiplied when the die cut is placed near

the strongest part of the box, a corner or an edge.

Die cut

holes can only weaken a shipping container's design and should

be eliminated whenever possible. However, sometimes the need

for localization holes (the customization of products for

international requirements) is unavoidable. The Packaging

Engineer should strive to design a structurally sound method for

localization.

4.5 Printing

Printing can

reduce the strength of a shipping container just as efficiently

as a die cut hole can. Printing words and/or graphics on the

outside of a container can cause damage. The pressure from the

printing rollers needed to obtain a good print will crush the

flute structure weakening the board.

A study

conducted by Colgate Palmolive Peet Company shows that a

corrugated container starts losing compression strength when

printing exceeds 20% coverage.

Laboratory

test results on printed and unprinted boxes will nearly always

favor the unprinted box. Laboratory technicians who suspect that

excessive printing pressure may have been the major cause of

failure may dissect box panels after compression tests and

caliper board thickness on the printed and unprinted areas. The

difference will be "printing pressure." Typically, the results

will be rated against the following standards: A-flute - .015",

B-flute - .013" and C-flute - .011". If these maximums are

exceeded, the box maker should be advised to make adjustments on

their printer.

4.6 Size

It is

important to control the size of the container so it can fit

properly on to a 40" x 48" pallet. If the container is designed

too large then there will be overhang. Overhang prevents the use

of the strongest elements of the container, the corners and

edges. The stress is placed on the bottom panel which fails.

Another possible problem with oversized container is that they

are placed on their sides to obtain optimum cube on a pallet.

This places the corrugation of the body panels parallel to the

compressive forces reducing the strength of the container. The

flap panels become the load bearing surface and quickly fail.

Most recent

tests, under tight laboratory conditions and pre-conditioning of

the packaging, showed a 50% difference in strength between a box

with vertical fluting vs. horizontal fluting.

4.7 Inserts

Corrugated

insert are mainly used to separate products but can be employed

to increase the structural strength of a shipping container.

Information on the effects of some of the more common corrugated

interiors on box compression can be found in the "Compression

Guideline" available from Corporate Packaging Engineering

(address and phone number on the bottom of the page).

5.

Standards

5.1 United

States Standards

The

standards that control how corrugated boxes are made in the US

are "Railroad Classification Rule 41" and "National Motor

Freight Classification Item 222". The most effective way to get

a copy of these rules along with other useful information about

corrugated (which some of this section came from) order the

Fibre Box Handbook.

These

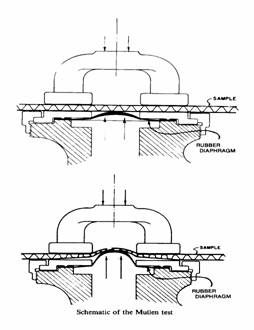

standards, Rule 41 & Item 222, are based upon some very basic

tests that do not represent the corrugated container's actual

strength. These tests are the Mullen burst test (which tests to

see how much pressure it takes to pop a hole in the corrugated)

and minimum combined weight of facings (which looks for how much

the corrugated weights per thousand square feet and determine if

the correct weight of liners were used). Since neither of these

tests correlates to how the container will perform, the

corrugated industry is investigating edge crush testing as a

replacement for the Mullen burst test. The edge crush test

requirement will allow the designer to choose the type of

corrugated bases on stacking strength requirements

.

5.1.1 Box

Maker's Certificate

A corrugated

container must bear a legitimate box maker's certificate in

order to qualify for shipment by common carrier. The

certificate guarantees that the box was made to specifications

of the Fibre Box Association, and in conjunction with the

requirements of the various freight classification agencies such

as the American Trucking Association, Inc.

The

certification must include the results of a burst, puncture, or

edge crush test; the results of the minimum combined weight of

facings; the size limit; and the gross weight.

For more

information regarding the information contained within the Box

Maker’s Certificate refer to the Fibre Box Handbook which can be

ordered through PPO order or contact Corporate Packaging

Programs at the phone number at the bottom of the page.

5.2

International Standards

Standards

for corrugated in the international community differ from

country to country. Therefore, it is difficult to present that

data here.

It has been

observed that the US Rule 41 and Item 222 will meet most other

countries requirements.

6.

Closure Requirements

If boxes are

improperly or carelessly closed, their carrying qualities are

lessened - an invitation to pilferage and to other loss or

damage.

6.1 Closure

Performance

The package

closure's primary function is that of containment. In addition,

the closure must:

·

Maintain interior cleanliness and ensure that contents remain

intact during shipping and handling.

·

Permit access to the contents for inspection without destroying

the usefulness of the container.

·

Not

create a safety hazard when the package is opened or allowed

contents to spill.

·

Conform to all applicable carrier regulations.

6.2

Preferred Closure Materials and Methods

Preferred

materials for closure of corrugated cartons are reinforced (non-asphaltic)

water-activated gummed paper tape (kraft color) or

pressure-sensitive transparent plastic tape, minimum width of

2".

Strapping is

an acceptable form of closure and is commonly used when securing

a container to a pallet.

Other

sealing techniques, such as staples and adhesives, usually cause

significant structural damage when cartons are opened along with

becoming a possible safety hazard and therefore should not be

used.

Containers

for contents weighing less than 70 lb. can be sealed with only

two strips of tape on the top and bottom center seams. The tape

should extend a minimum of 2 1/2' over the edge of the

container. Heavier contents requires additional tape along the

other top and bottom edge seams.

|